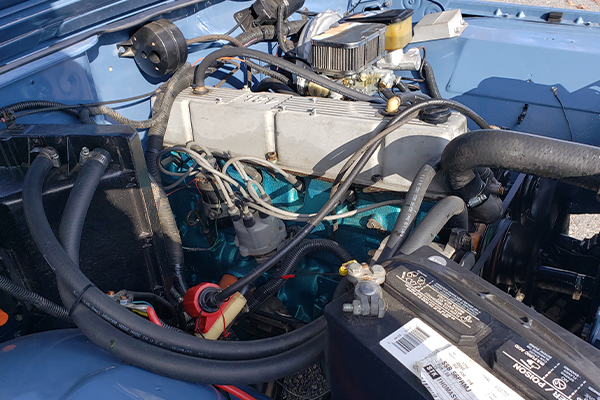

| 4.2 liter inline six | 4 speed manual transmission | Repainted original Montana Blue |

| 3in Rough Country Lift Kit | 33×10.5 BFG All-terrain Tires | 15in Chrome “Wagon Wheels” |

| Original Dealer Installed Roll Bar | Retro Styled Amber Fog Lights | Spare Tire Mount |

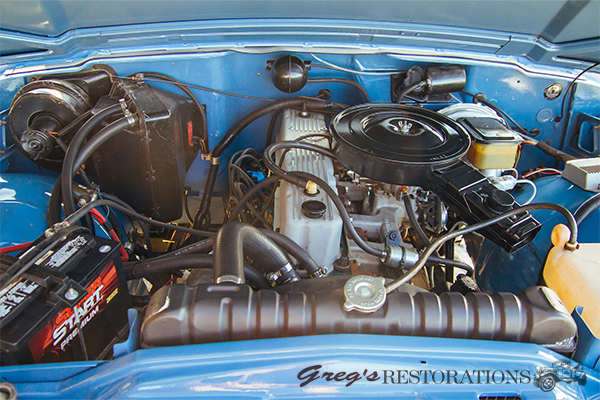

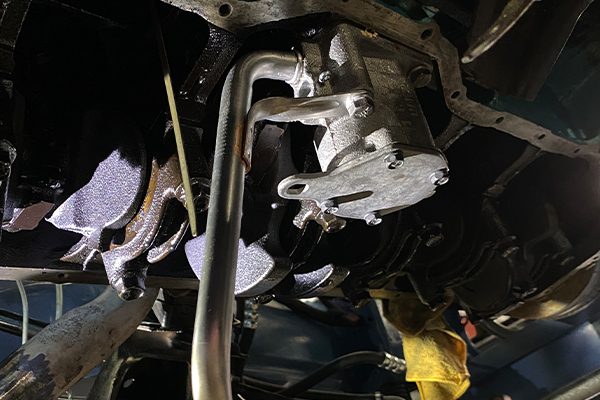

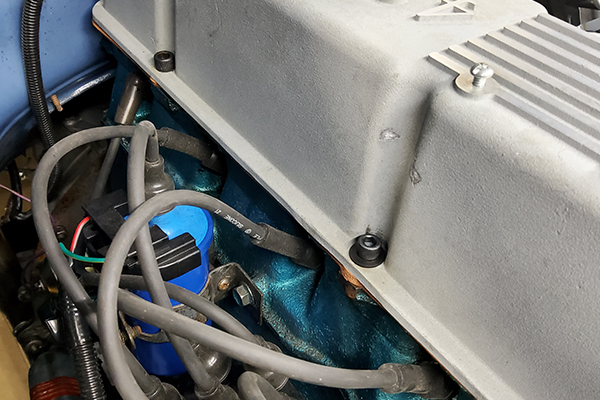

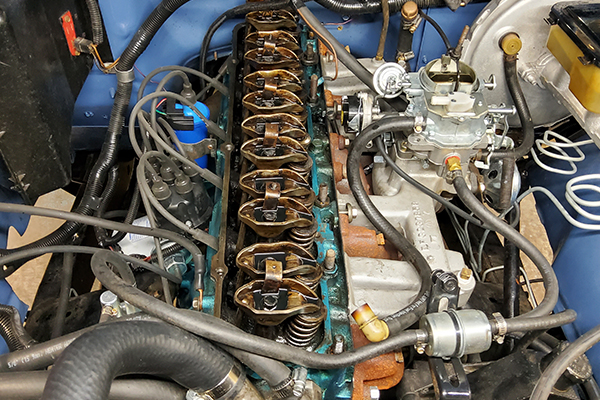

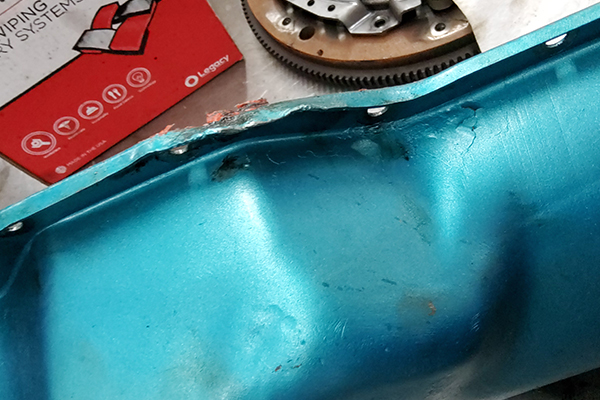

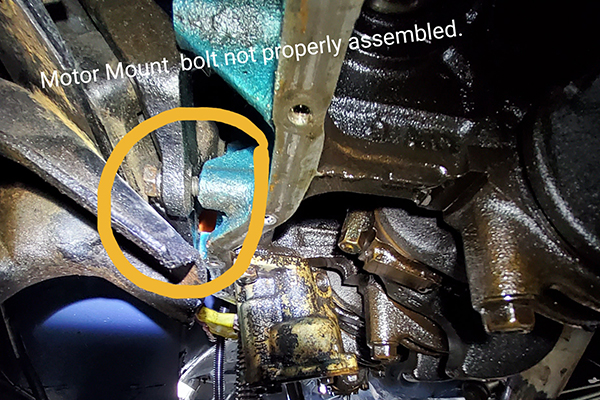

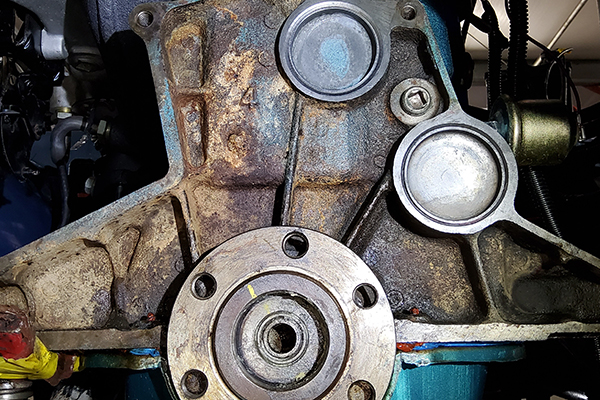

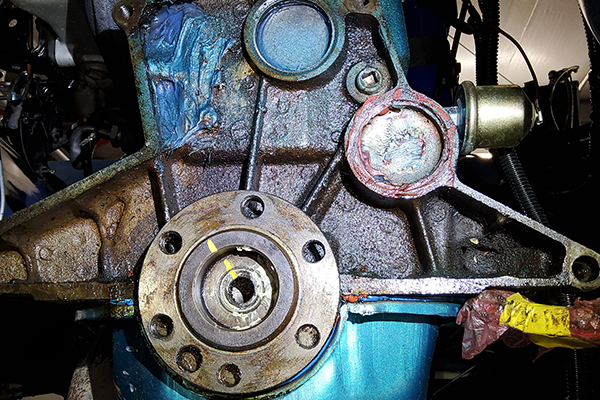

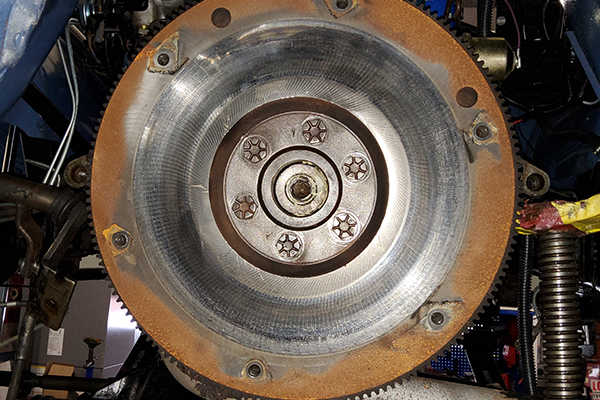

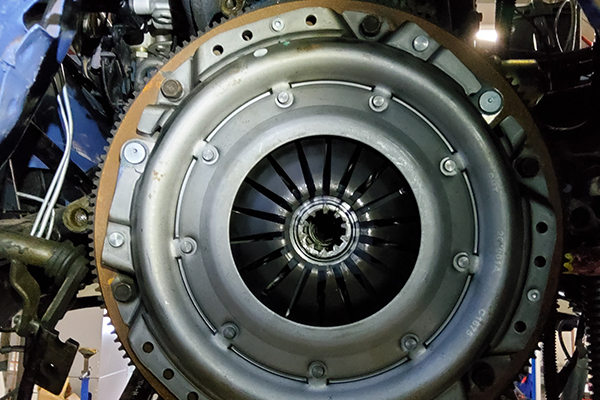

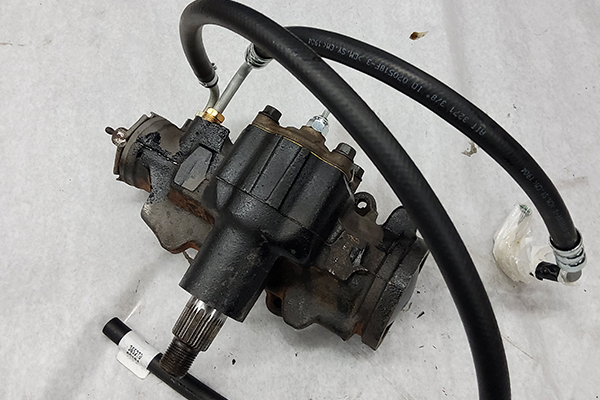

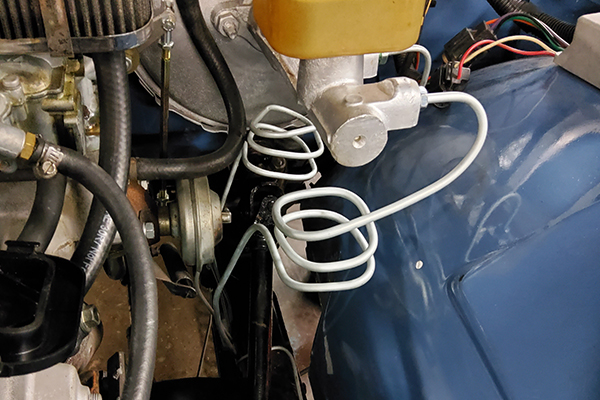

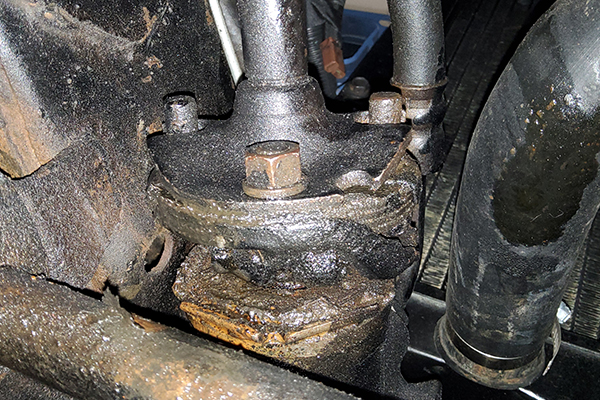

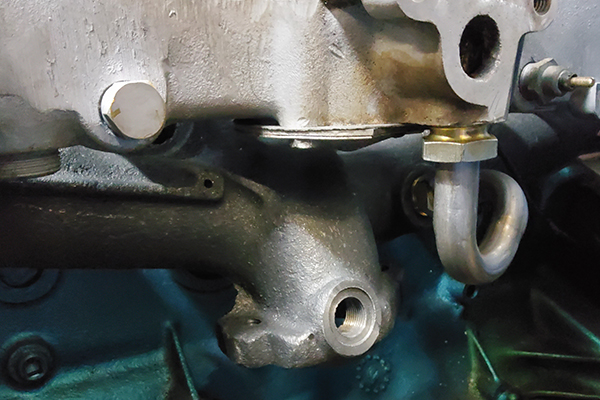

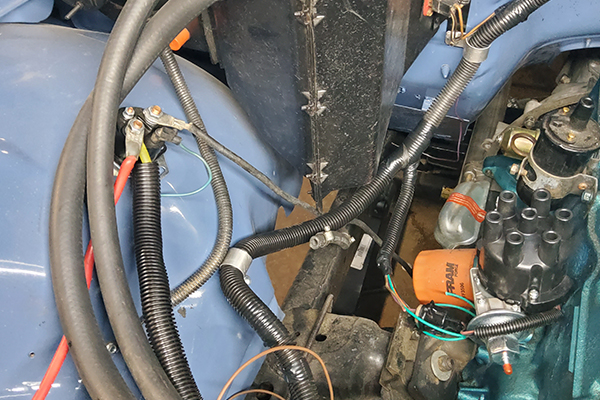

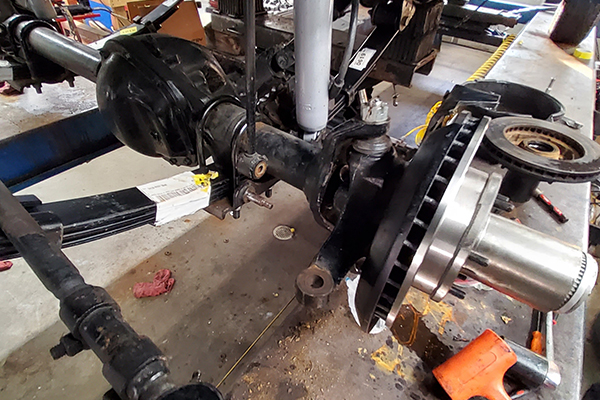

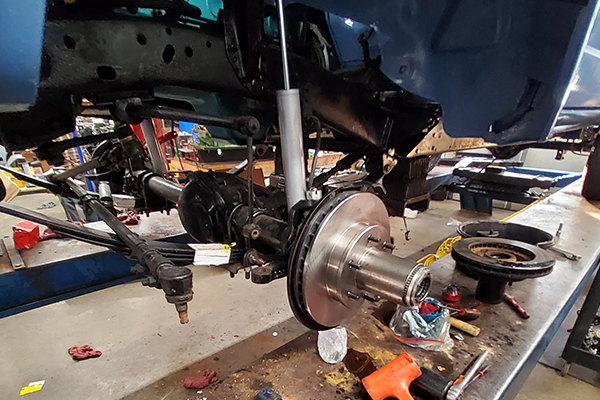

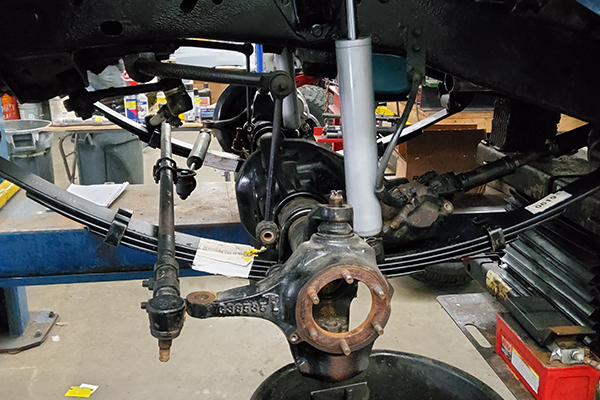

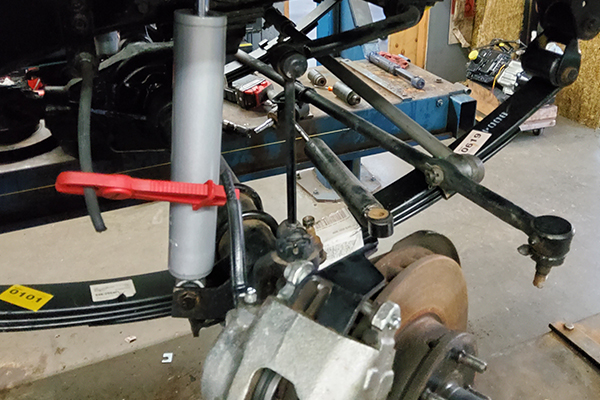

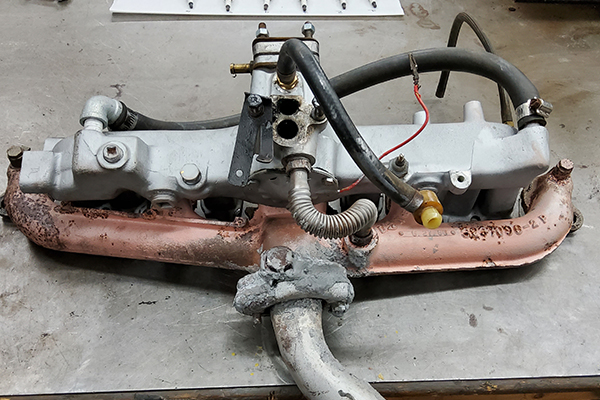

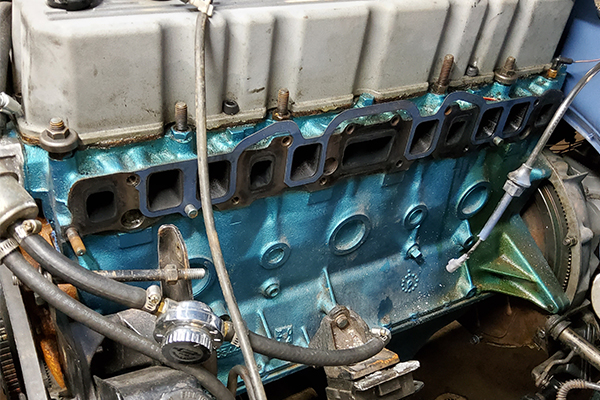

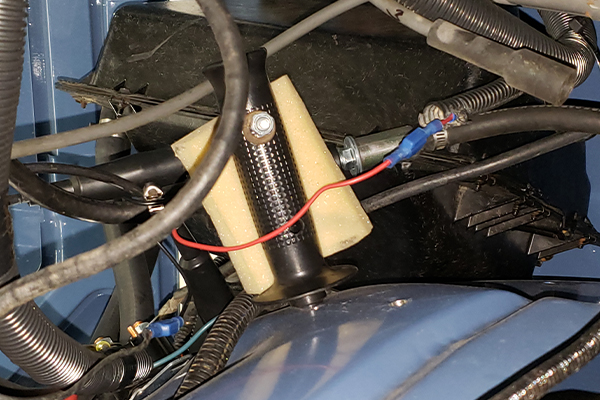

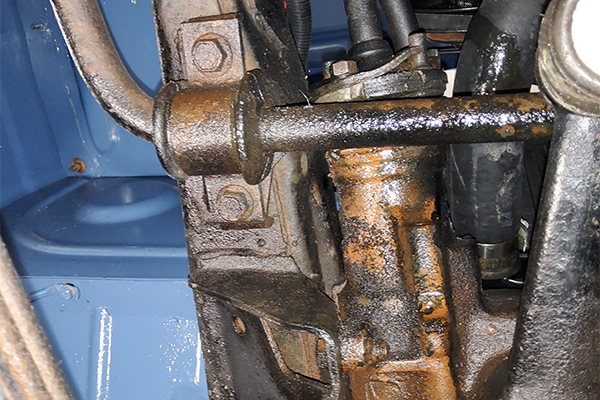

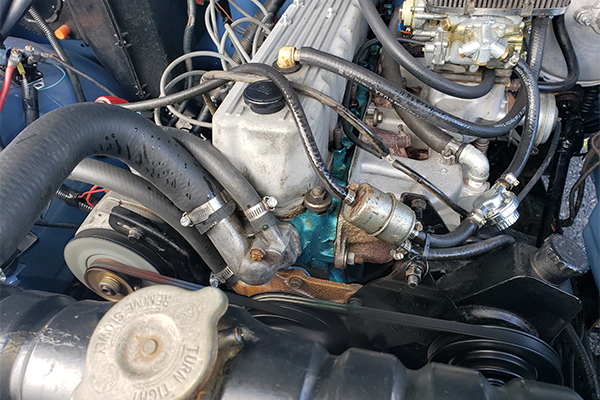

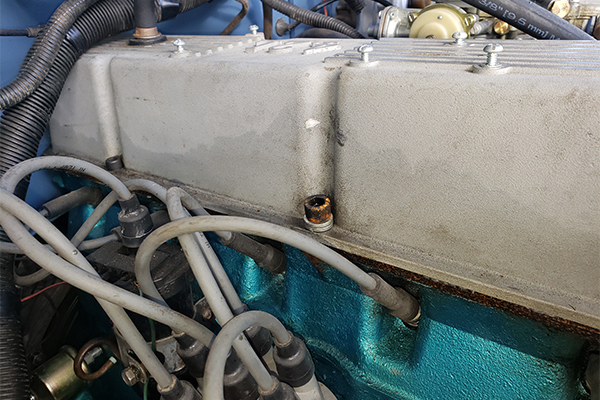

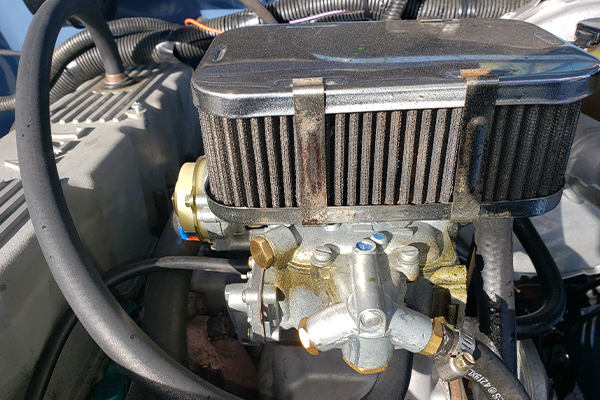

Though described as “running and driving” the truck was nearly undrivable. The aftermarket Weber carburetor would ultimately be changed out for an original style carburetor and a thorough tune up would get the engine running like it should. After the truck was running correctly the focus turned to fixing the previous owners “repairs”. Things on the list would include: adding a fan shroud, adding a coolant overflow reservoir, adding a proper radiator cap, recoring the radiator, replacing the gas tank as the current tank was cracked and had been epoxied shut, rerouting and redoing the entire fuel system as an electric in line fuel pump had mounted using a sponge and an angle grinder handle and lastly rewiring most of the truck. The biggest challenge that arose was the clutch system, the during the truck’s previous rebuild and engine and transmission were mixed and matched with other Jeep parts from various years (most likely a late 70s CJ7). The clutch pedal was hard as a rock, engaged like a light switch and inconsistently worked. The clutch components were all brand new, the old parts were long gone and with not knowing what the previous owner had done the trouble shooting began. We would end fabricating a system made of J10 and CJ7 parts and even machining our own throw out bearing to fit to give the proper amount of pressure plate actuation. At last, it was time to move onto the modifications. A three inch Rough Country lift and 33 BFG inch tires on a larger factory style chrome wagon wheels would set things a motion. The search was then on for an extremely rare factory option, the roll bar spare tire carrier combo. Once acquired the bar was fixed up and modified to fit one of the 33 inch tires and a few old school fog lights to finish off the look and get the truck ready for the road.