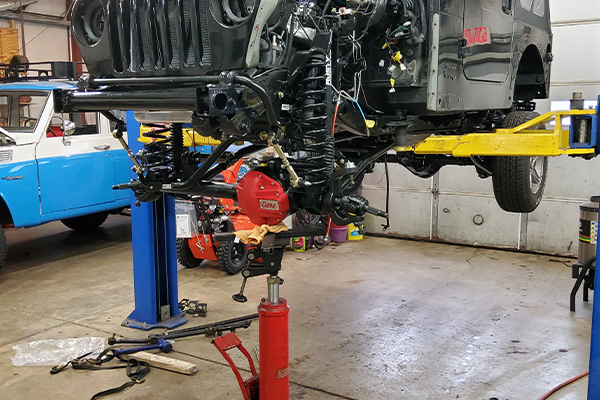

| Rusty’s Off Road 5.5 inch long arm kit | Fuel wheels | 35×13.5R15 Toyo Open Country M/T |

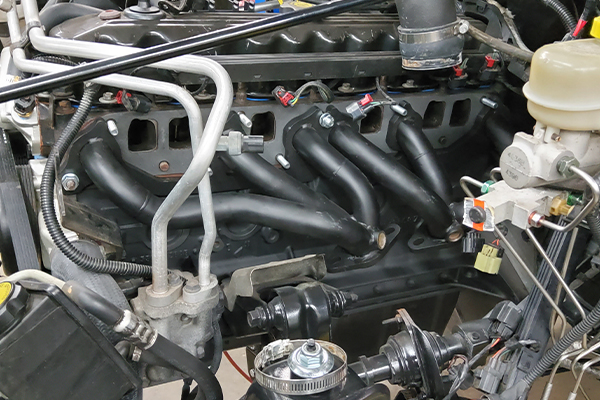

| Flowtech header and ceramic coated exhaust | Front bumper | 8000lb Warn Zeon winch |

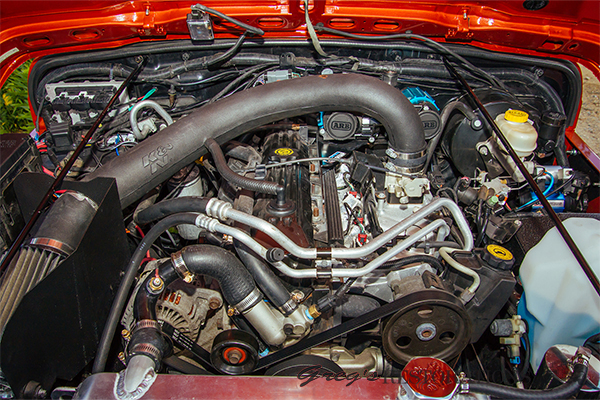

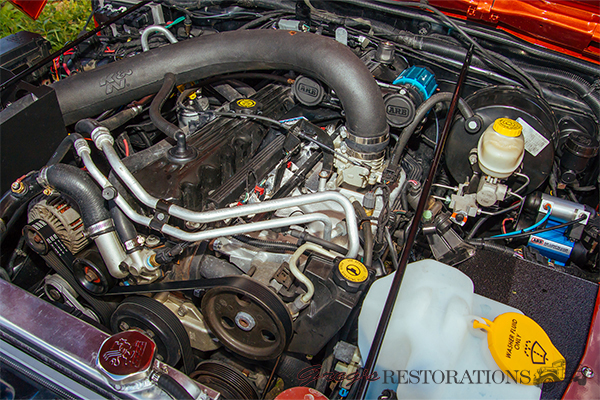

| Griffin radiator and fan setup | Metalcloak tube fenders | Rock Hard 4×4 Rear Bumper/Spare Tire Carrier |

| Garvin roof rack | Raptor lined interior | Burnt Orange Metallic paint |

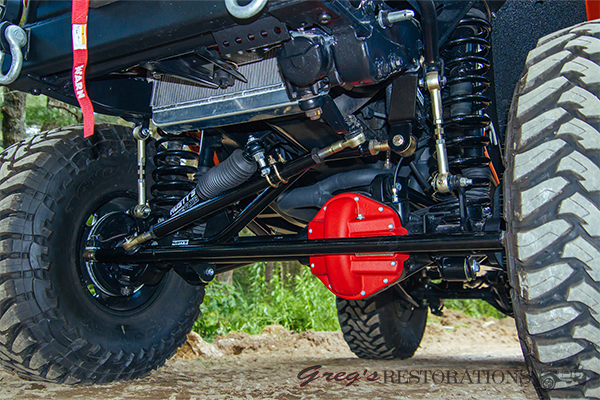

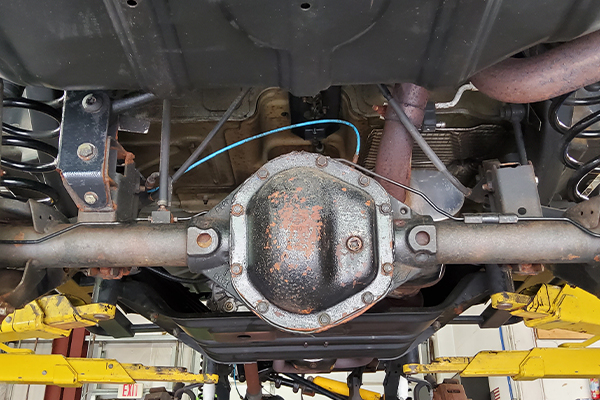

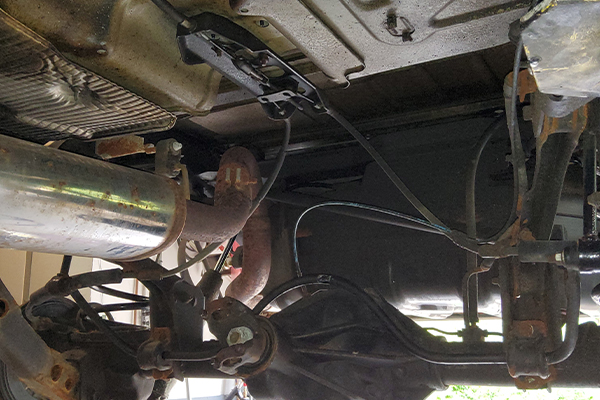

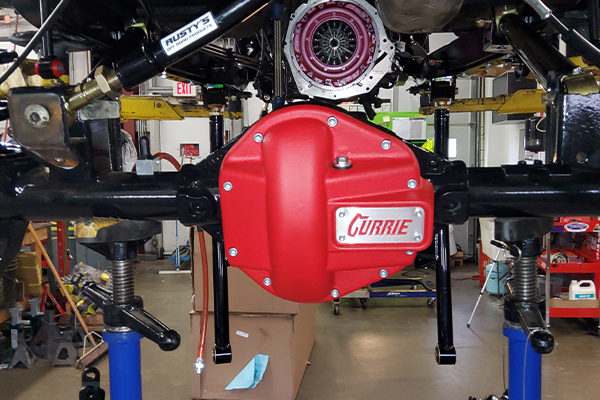

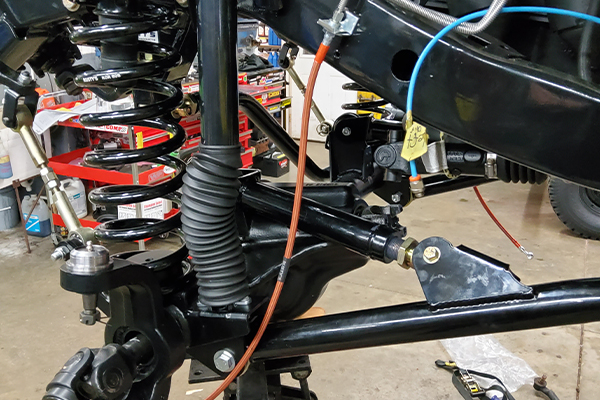

| Currie built “Dana 44” front axle | Dana 44 rear axle | On board air |

| Dual ARB air lockers | Katzkin two tone leather seats | Body Armor rock sliders |

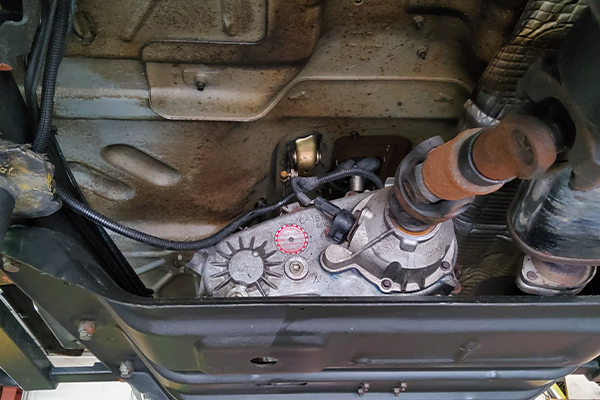

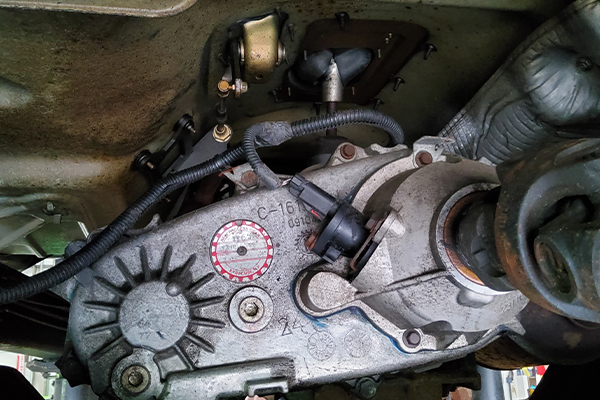

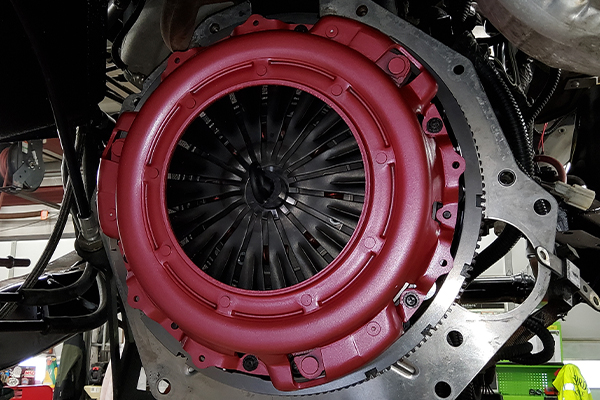

| Ram twin disc clutch | Slip yoke eliminator kit |

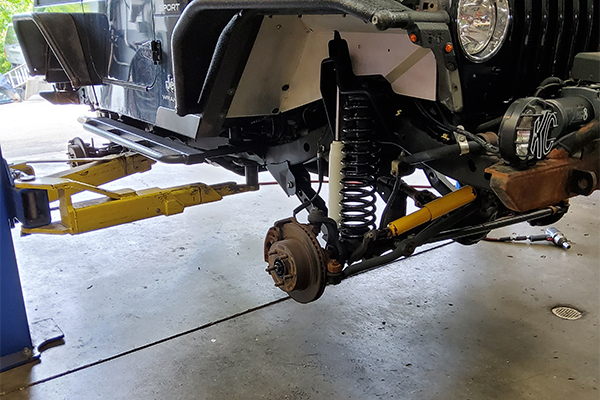

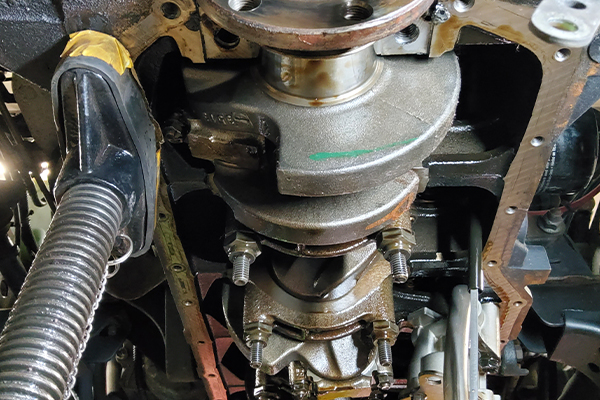

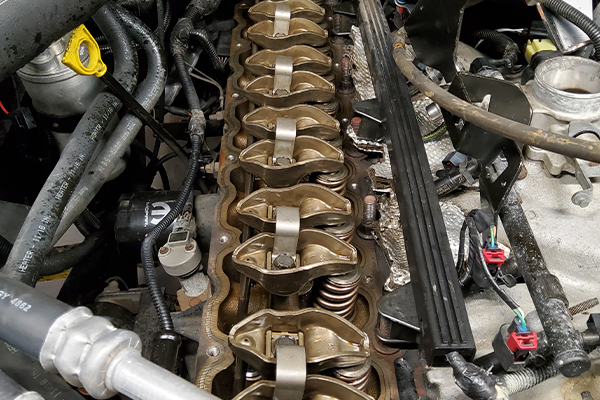

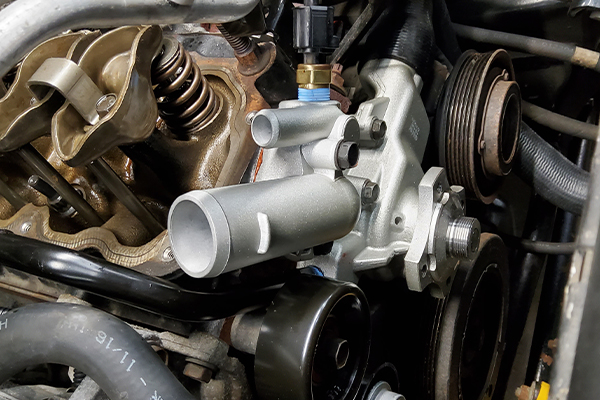

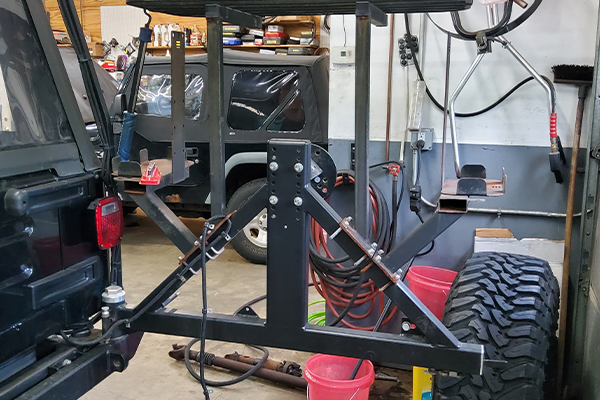

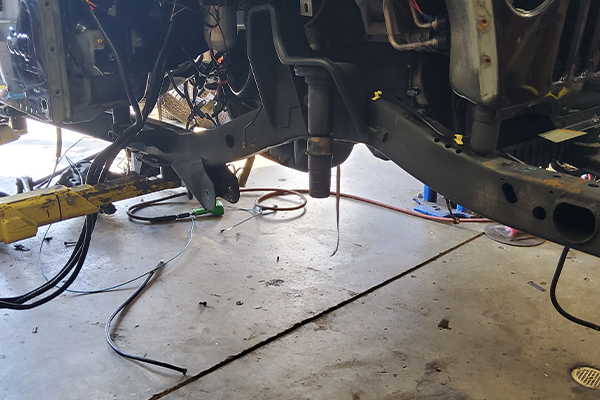

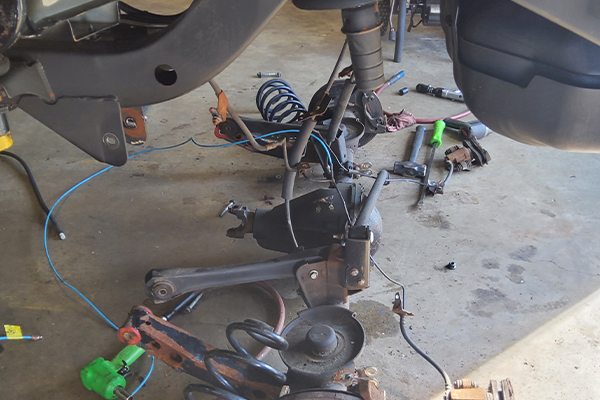

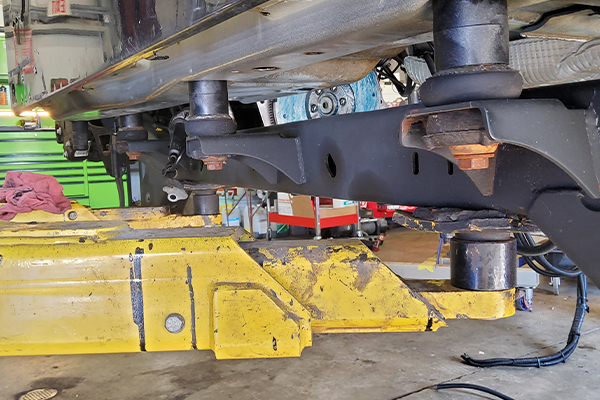

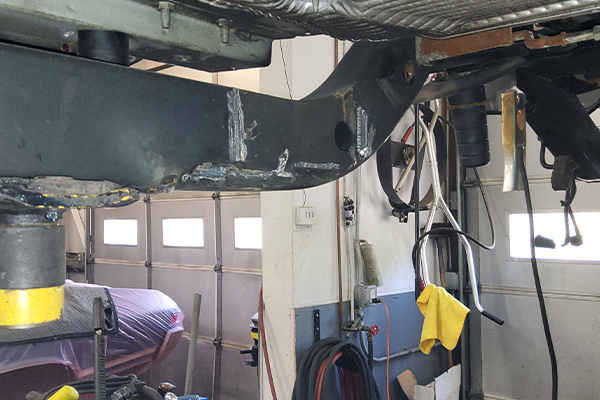

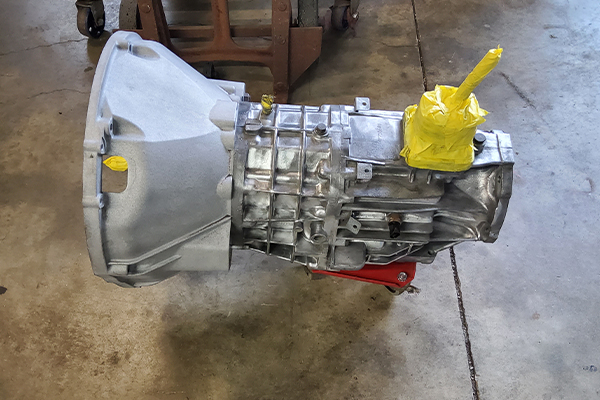

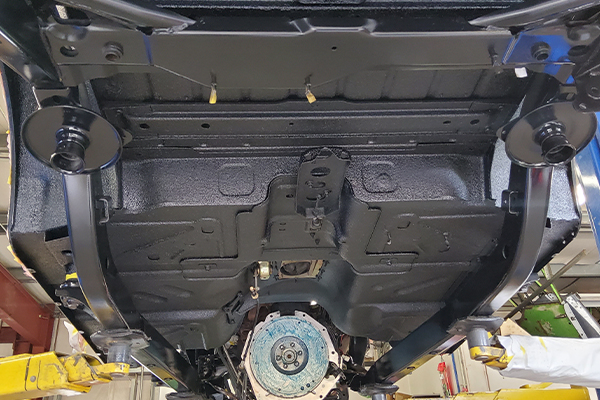

First on the list and most important was the lift kit. The Jeep arrived with a standard bolt on suspension lift that utilized factory mounting points and a set of body spacers. Though fine for the average trails it was not the best choice for serious four wheeling. The solution to this was Rusty’s offroad long arm kit, a system designed for maximum articulation and suspension travel. Installation of the kit is a very involved process and requires removing the welded on factory suspension brackets and smoothing out the frame then attaching the kit’s new bracketry to their transmission mount/skid plate. Next on the list was getting rid of the weak Dana 30 front axle. For this we went to Currie Industries for a fully custom built Dana 44 axle. Currie’s “Dana 44” may resemble a regular Dana 44 but everything on the axle is built handle the toughest terrain and biggest tires. With 4.56 gears, ultra high strength 4340 axle shafts and ball joints, ARB air locker, high pinion style differential, thicker axle tube walls made from DOM tubing, larger U joints and a reinforced center section makes this axle is a serious unit built to last. In the rear is a matching factory Dana 44 axle with ARB air locker and Currie armored differential cover. Throughout the body there are many added offroad items, the front features a Rock Hard 4×4 winch bumper with a Warn Zeon 8000lb winch, in the rear a Rock Hard 4×4 rear bumper/spare tire carrier and cargo basket and mounted on top is a Garvin Expedition rack with numerous lights. The restoration of the body was straight forward since the Jeep had zero rust and very low mileage, so underneath the entire body was wire wheeled then undercoated and the frame would be wire wheeled and epoxy painted. Inside of the tub would be raptor lined to the edges of the tub where it transfers to a Burnt Orange Metallic paint. Mechanically the driveline would need little as well, so the driveline was resealed, a Flowtech exhaust manifold, ceramic coated exhaust and twin disc clutch were added. To finish off the build the interior was redone in Katzkin two tone leather, a huge upgrade over Jeep’s basic utilitarian seat upholstery. From blacked out to burnt orange almost every surface of this Jeep was improved in look and function.